PP sheet black Masterbatch a masterbatch with good ductility and strong dispersibility. Plastics with the masterbatch added can be extruded or rolled to a thickness of about 0.1-2.0 mm plastic rolls. The sheet grade black masterbatch is usually universal with film grade black masterbatch.

2.Technical Parameter

Index | Value |

Appearance | 2.5*3.5 mm granules |

Carrier | PP, PE or Customized |

Carbon Black Content | 15-45% |

Color | Black |

Ratio of dosage | 1-5% or As your requirement |

Melting point | 120ºC |

MFR(26KG/190ºC) | 30-50 g/10min |

Volatility(<%) | 0.1 |

Compatibility | PE/PP/PVC/ABS/PS |

Eco Friendly | ROHS(SGS) |

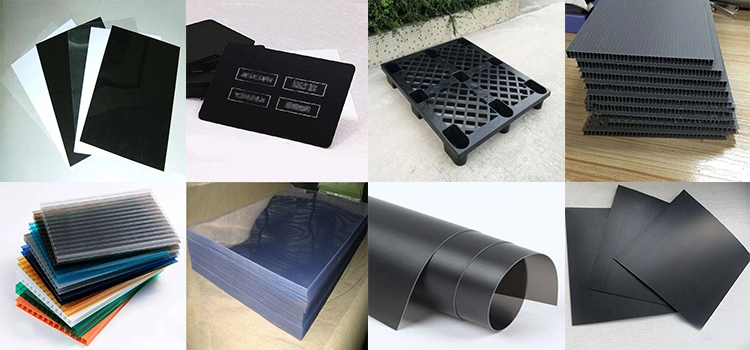

3.Application of pp sheet black masterbatch

Sheet grade Carbon black masterbatch is widely used in disposable plastic cups, plates, bowls, dishes, packaging boxes, and it can be used in the vacuum forming industry and plastic printing industry, including various black sheets, pp sheets, pe sheets, sheet products.

4.Advantage of using sheet grade black masterbatch

Bright color, better tinting strength

Ensure masterbatch uniform distribution in the polyolefin resin processing,

keep physics performance of the thing itself

Good machining property, more smooth surface

Better hiding power, dispersibility, flowability and compatibility

5. Our testing Equipments for control quality

Universal Material Testing Machine

Desktop spectrophotometer

Pendulum impact test apparatus

Melt flow rate testing instrument

In addition, there are electric furnace temperature controller, moisture analyzer, carbon black content testing instrument, impact test apparatus and other test instruments.

We can test the samples sent by customer and produce the products that the customer needs.

6.Packaging & delivery Of sheet grade black masterbatch

Packaging Details:

--------packing of sheet black masterbatch: Paper plastic composite bag, N.W 25 kg/bag. Please store in the dry place.

--------delivery Time: 5~7 days after confirming order

7.FAQ:

Q:How to use masterbatch?

A:Simple for using, just mix up with the resin granules according to the dosage ratio under appropriate temperature.

Q: What are the advantages of our shipping and delivery?

A:1.We make sure all the products will be inspected strictly before loading.

2.We will make the shipment within 7 days after confirm the payment.

3.We will recommend the best suitable shipping company for our customer from different countries. Saving cost for our client!

Q: What our products can be used to?

A: PE / PP / PC / ABS / PET / PBT / HIPS / GPPS / PA / PVC / PMMA / POM / PU

Q: What's more?

A: Free samples are available. We can help to provide the design for your products.

8.Why choose us

+. Advanced production technology, constant innovation

+. Each product passes though rigorous test , the quality can be guaranteed and reliable

+. Reasonable price

+. Strong production capacity, high speed delivery

+. Has been certified by ROHS & SGS & ISO9001

+. Modern production and testing equipment

+. Good quanlity and competitive price

+. A broad standard type range available from the stock as well as tailor made products develop according to customer requirement.

9.Our Company and certificationsQingyun Xinyang New Materials co., Ltd, located in Shandong Province(the northern area of China), has been one of the biggest masterbatch manufacturers of China since it establishment in 2009.

Color masterbatch, defoaming masterbatch and filler masterbatch are available and widely use in the field of filler blowing, injection molding, pipe, sheet, electronic cables and so on. All the products are carefully put through quality-controlled inspections

10.Contact